Watch our Friends at the Jeep Farm do a Howell TBI install on a FSJ Cherokee with a DUI ignition system.

Tech

Howell EFI Tech Articles

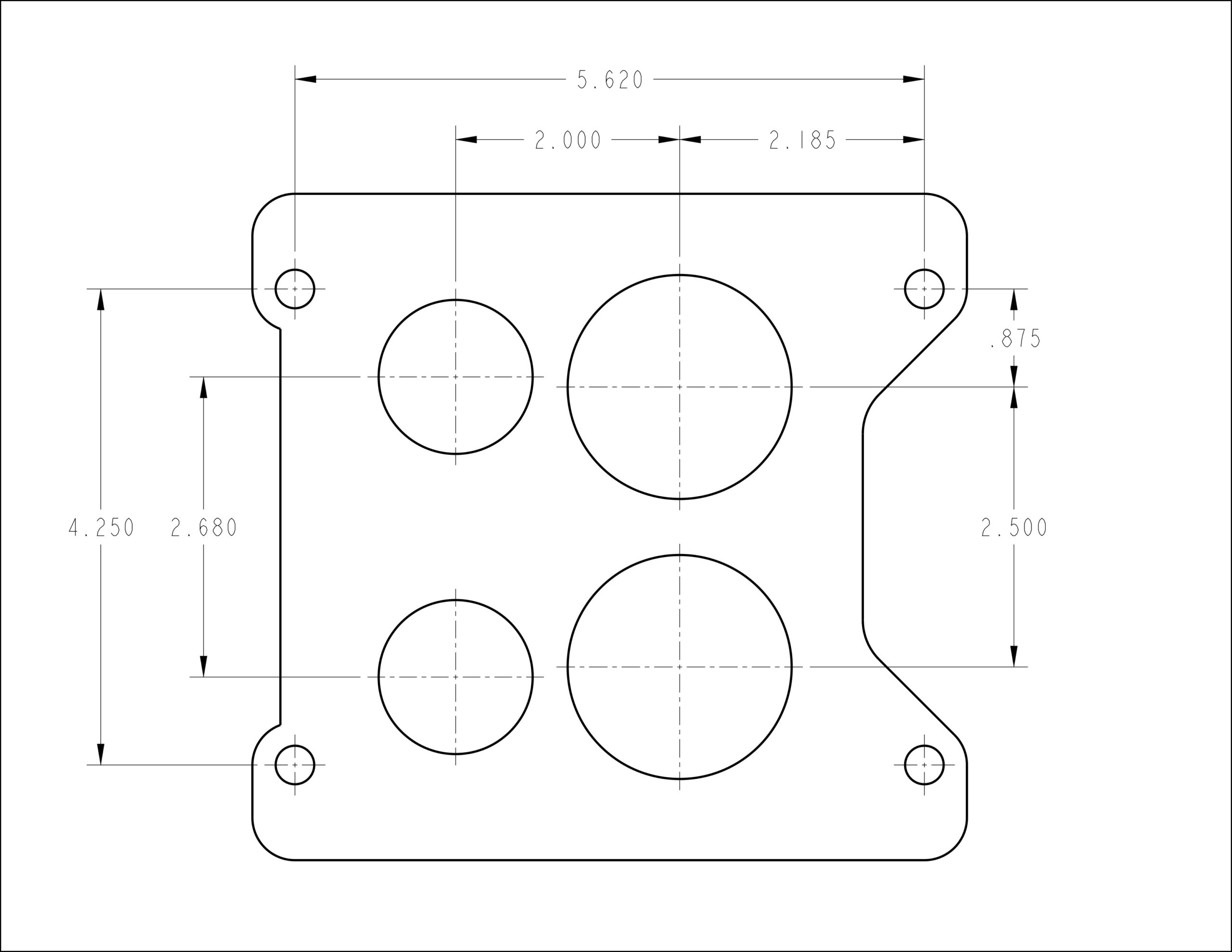

Before ordering your Howell TBI conversion kit, there are a few important things to check on your vehicle to ensure proper installation and function. Inlet…

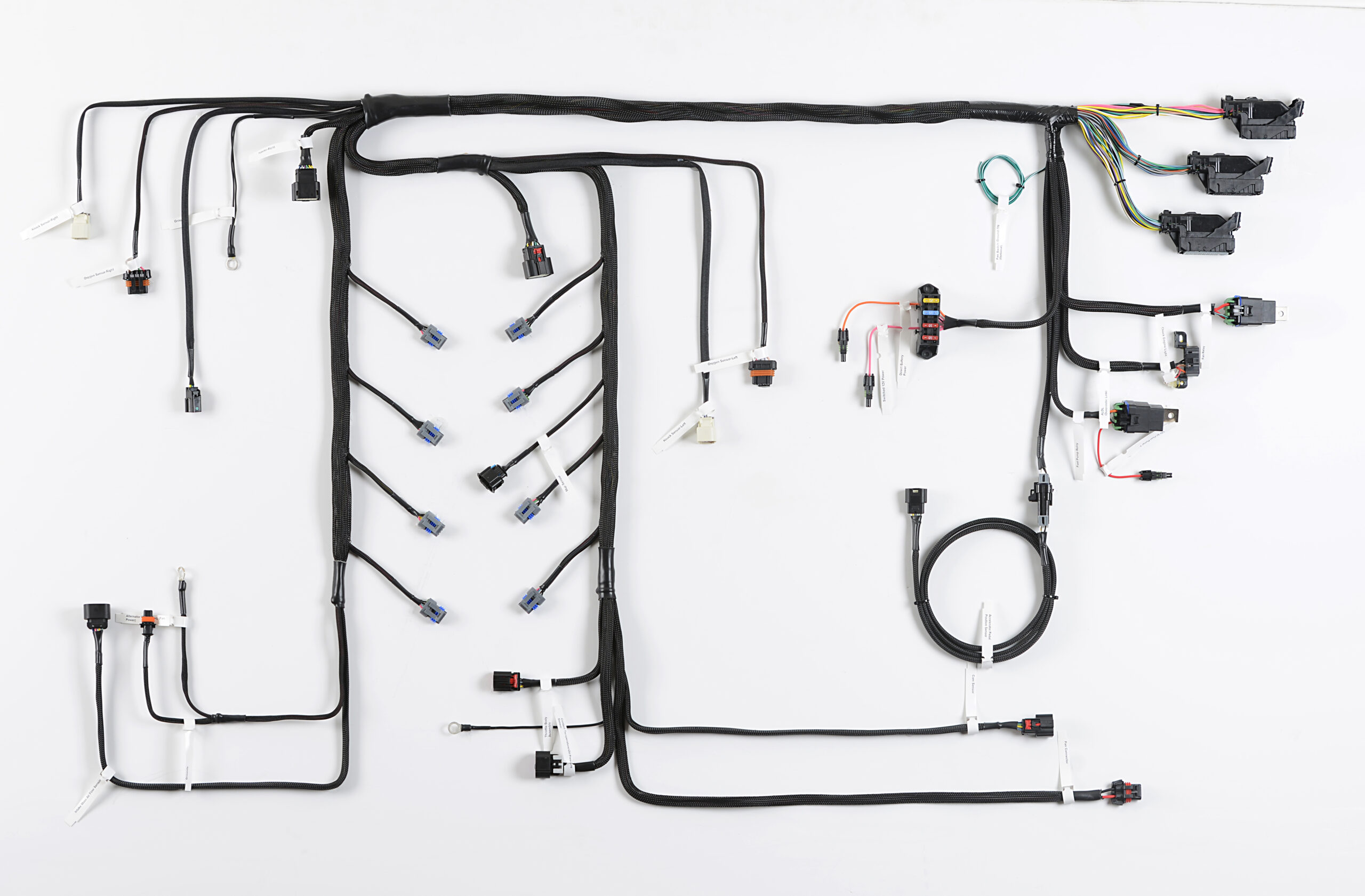

A custom wiring harness and kit are the only way to go with Electronic Fuel Injection conversions. Not all vehicle builds are the same. That’s…

Howell EFI Conversion Kit Helps Kick The Carb! No vehicle on the road (or off road) benefits more from swapping from a classic carburetor to…

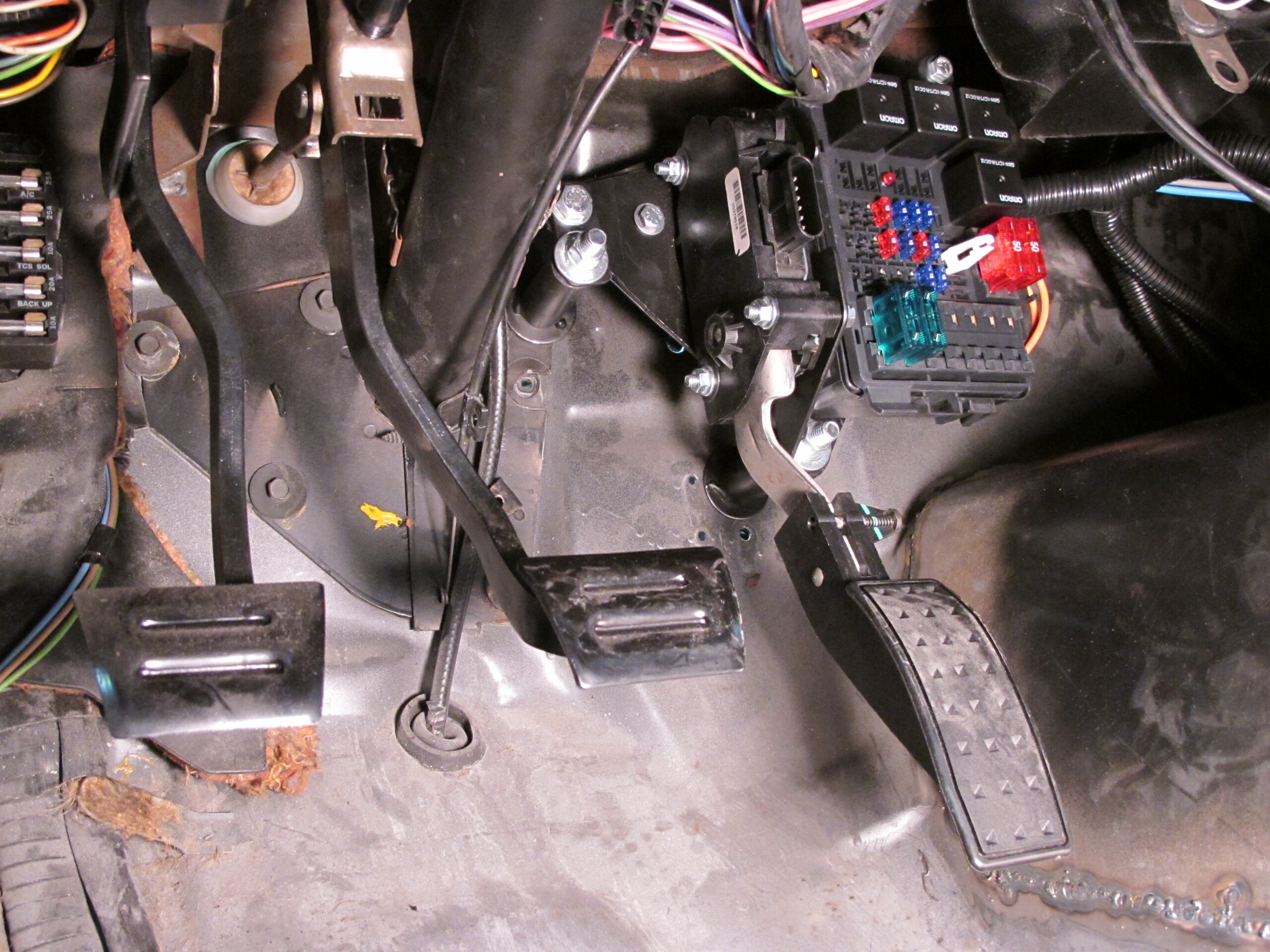

With many of their electronic fuel injection conversions, Howell EFI includes a drive-by-wire (DTW) pedal assembly that must be mounted in the new vehicle to…

Howell EFI, well respected in the industry for their plug and play EFI systems has earned that reputation for a reason. Their customer support team…