Marine City, MI, (October 3, 2024) – Howell EFI, a leading manufacturer of electronic fuel injection conversions, announces new LS and LSA swap harnesses and components…

Author Archives: howellefi

Watch our Friends at the Jeep Farm do a Howell TBI install on a FSJ Cherokee with a DUI ignition system.

Marine City, MI, (February__, 2024) – For 35 years, Howell EFI has been a leading manufacturer of electronic fuel injection for older pre-computer vehicles of…

Howell TBI Conversion Kits Now Available for 1974-1993 Dodge Ramcharger and Plymouth Trailduster SUV

More consistent tune and improved cold starting for Gen I and II vehicles Marine City, MI (September 14, 2022) – Howell EFI, recognized as a…

Howell EFI offers eight different Throttle Body Injection (TBI) kits that can be used to convert classic International Harvester Scout trucks to TBI. Whether driven off-road, used for show or a daily driver, Howell’s TBI conversion kits are designed to convert classic Scouts (Scout 80, Scout 800, 810, Scout II) quickly and efficiently to fuel injection improving cold starting, drivability and fuel mileage. And for off-roaders, your Scout will be less likely to be fuel starved when taking the trail at an angle.

Marine City, MI (April 7, 2022) – Howell EFI is known widely in the industry for their easy to install GM-based EFI and TBI kits…

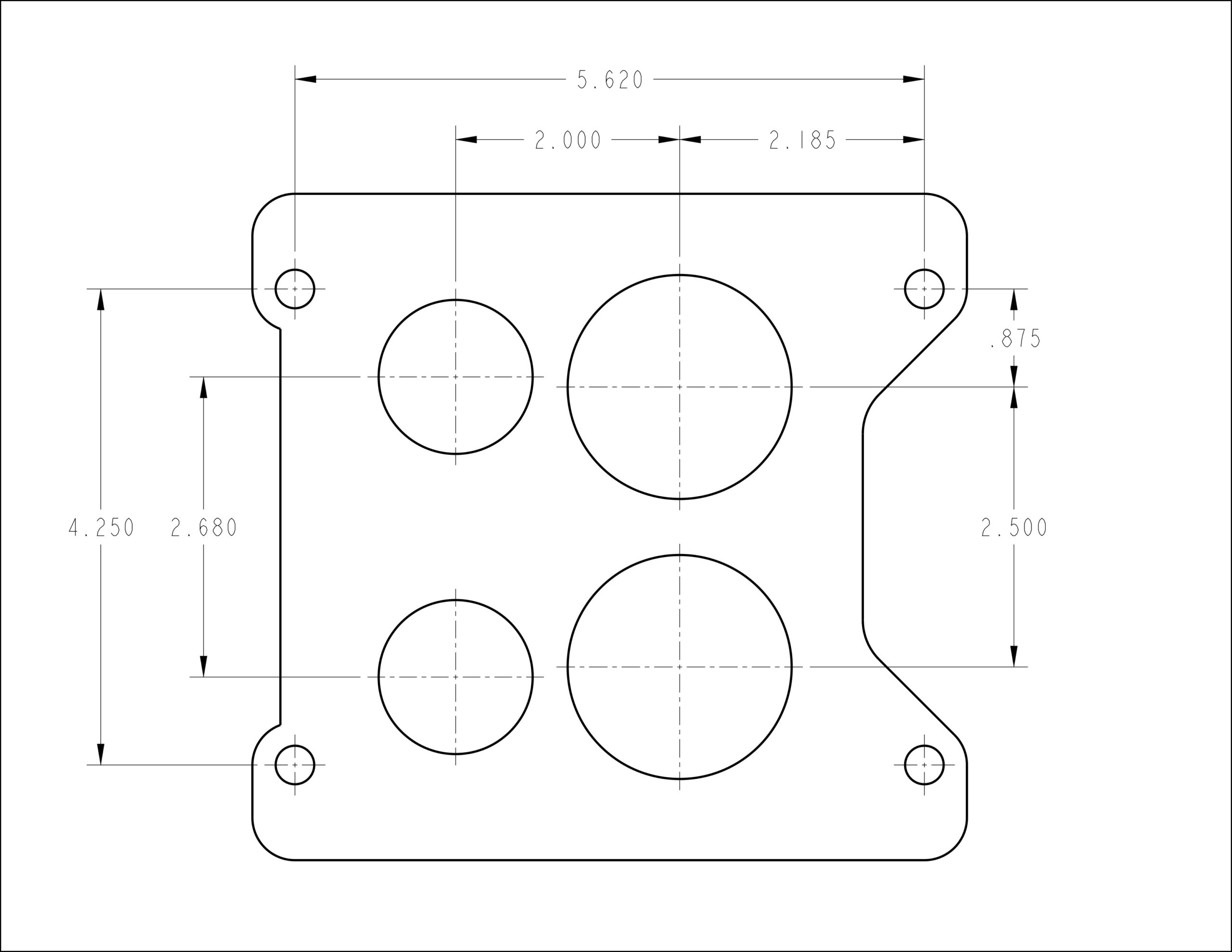

Before ordering your Howell TBI conversion kit, there are a few important things to check on your vehicle to ensure proper installation and function. Inlet…

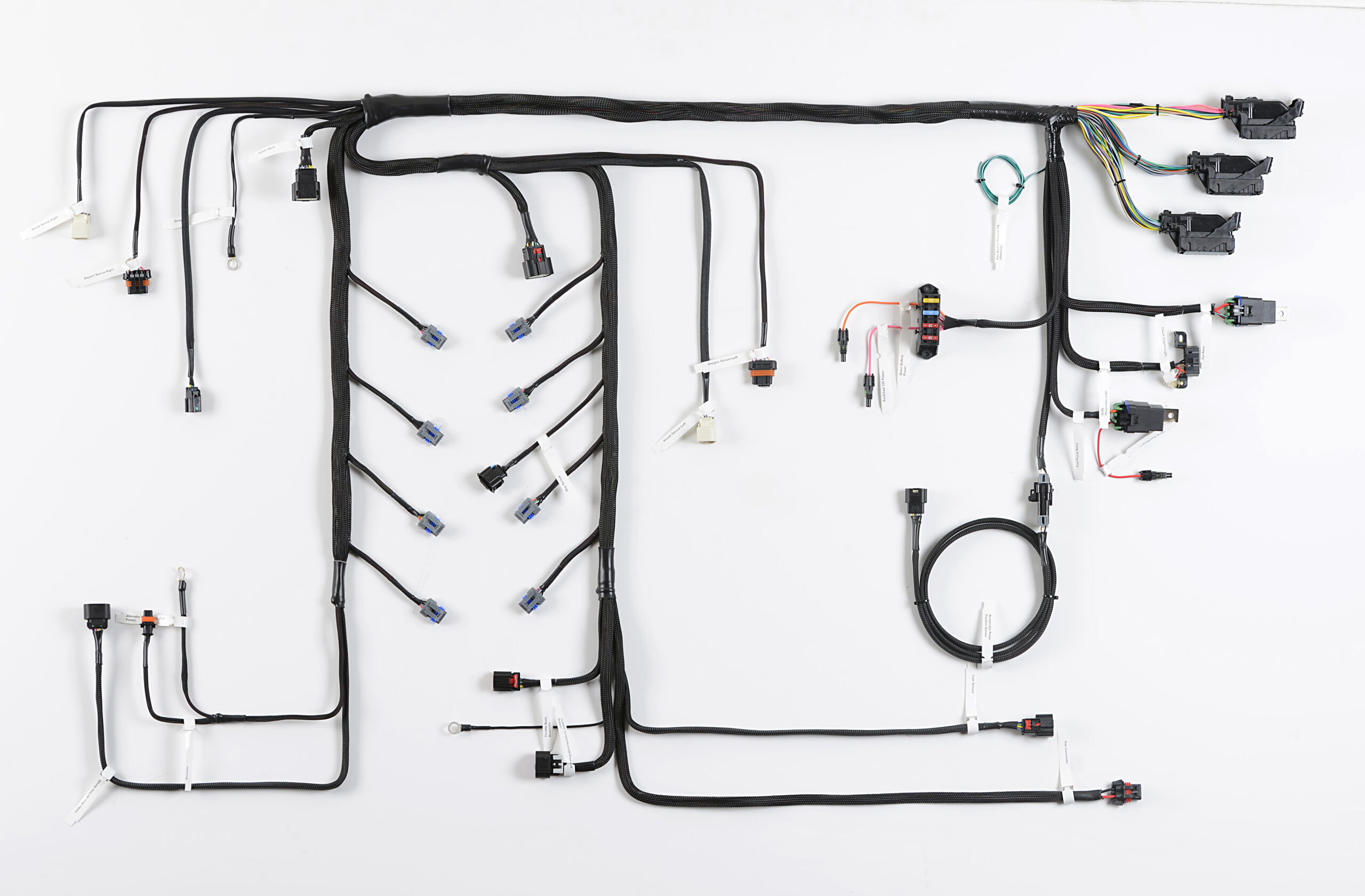

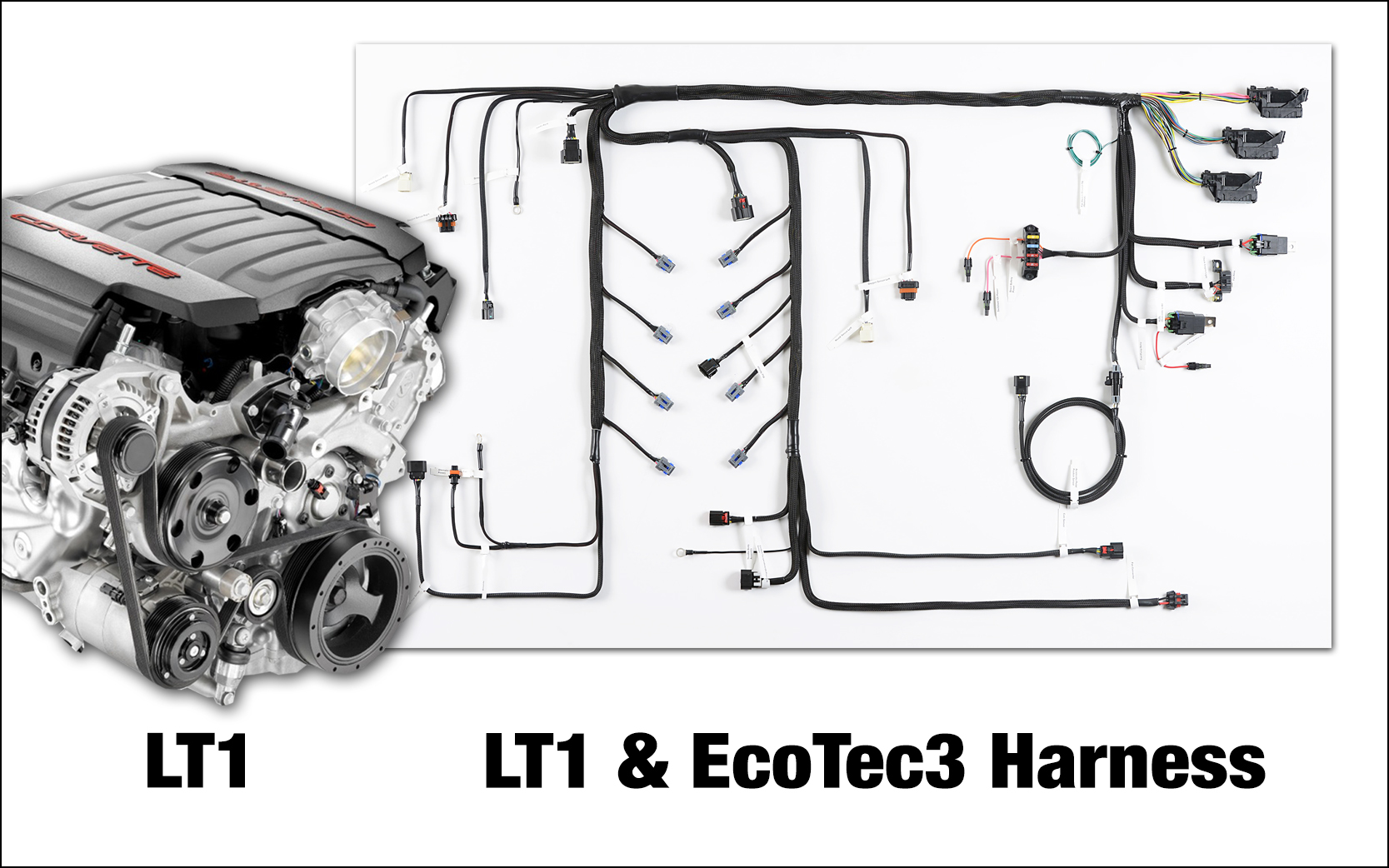

Marine City, MI… October 7, 2021 – Howell EFI, a leader in EFI conversion kits (GM/TPI/TBI) and wiring harnesses for direct injection swaps, now offers plug and play LT1/LT4 and EcoTec3 wiring…

Marine City, MI… August 26, 2021 – Automotive pioneer and industry legend, Billy “Bill” Haegen Howell, passed away on July 22, 2021, after a battle…

When necessity drives innovation, many good things can come from those with the ambition to create, design, produce and persevere their way into success.

Bill with friends, Mike Miller & Marilyn Bill recalls of his early retirement, in 1989 TV personality, Don Johnson had an ocean-racing catamaran with 4…