When necessity drives innovation, many good things can come from those with the ambition to create, design, produce and persevere their way into success.

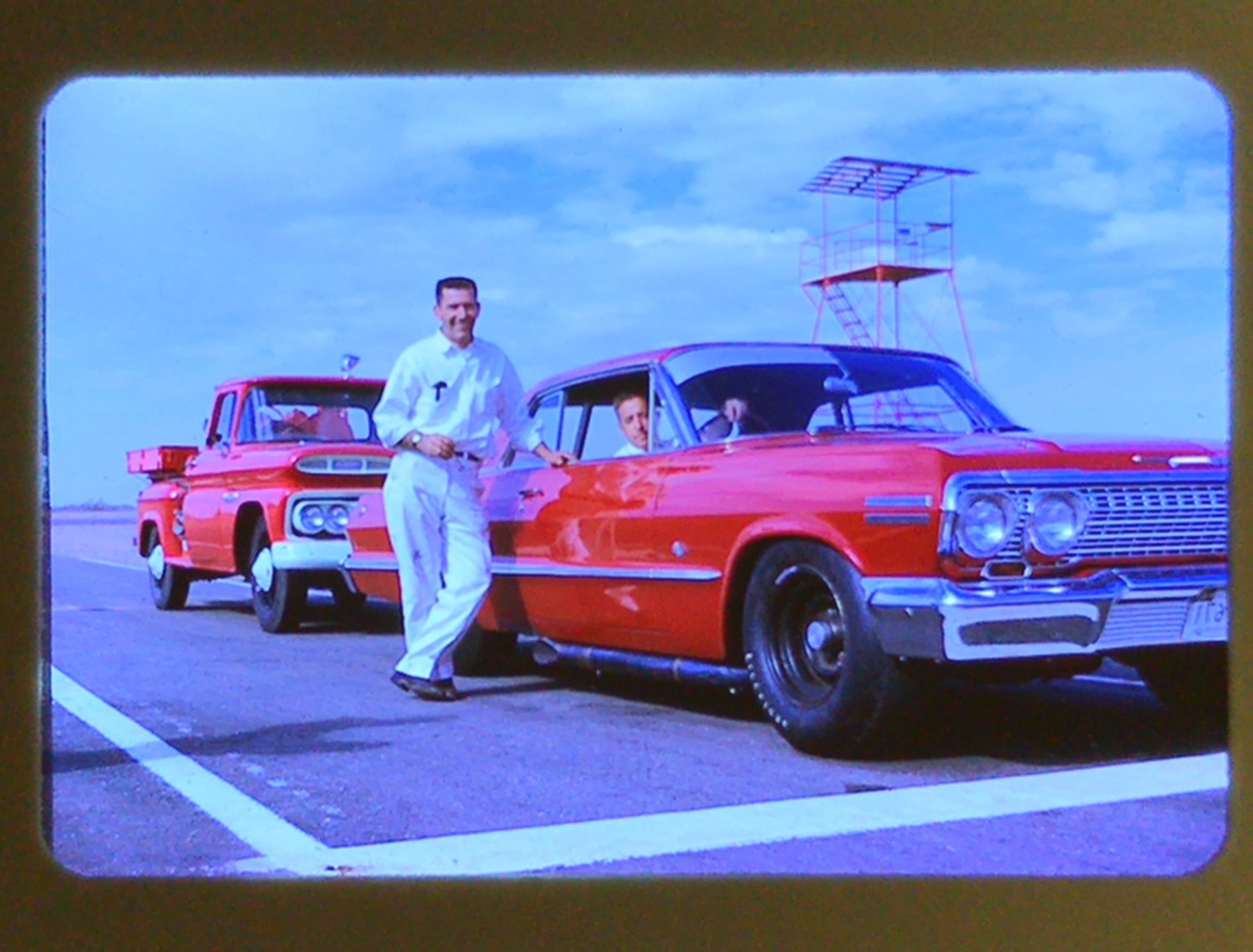

Bill Howell

With his short-lived racing career in the past as well as a pending divorce from his first wife, whom he met while living in Laramie…