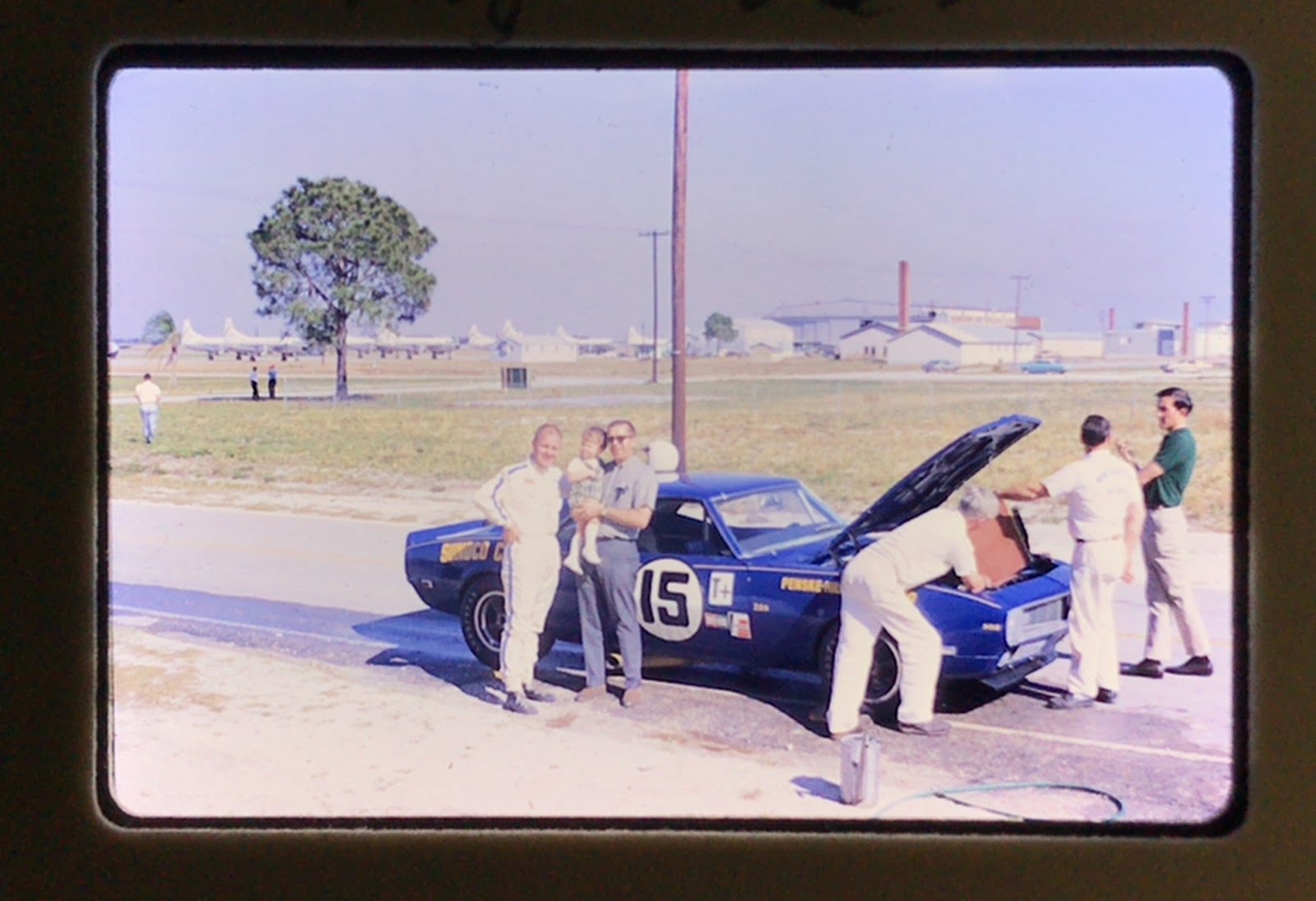

Sebring 1968, Bill & son, Matt with Mark Donahue

In 1968, Bill followed Trans-Am and Can-Am races. “We sold a number of pre-production aluminum 427 MK IV engines to several Cam-Am race teams. These cylinder blocks were cast using temporary pattern equipment that had formerly been used to cast the Chaparral engines by R&D,” says Bill. About this same time, Yunick had been working with Chevy R&D to develop a competitive Chevelle for use in NASCAR racing. “I don’t recall the details, but Curtis Turner drove it in at least one race, and it was destroyed in a wreck and never rebuilt.”

“In 1967, McLaren maintained their engines from Al Bartz’ shop in California. TRACO built and maintained the engines for Penske from California. The first TA race was the 24 Hours of Daytona. With primary driver Mark Donahue, we led the race off and on, but were hampered by slow brake pad changes and got behind the Fords. At 4:00 in the morning, we experienced overheating from a cracked cylinder head, which resulted in a 3-hour pit stop to change it. This had been a recurring failure, which we had not yet solved.”

Thereafter, Bill Howell was able to develop a successful vacuum assist to the braking system that solved the slow brake-change problems, which they put to the test during the Sebring 12-hour race in Florida. “We dominated the TA portion of the race, finishing first and second with Penske-entered Camaros. At all of these races, my job was to connect with other Chevrolet-based competitors to give advice and observe any component problems they may have had.”

The Yunick Camaro was entered and driven by Lloyd Ruby, but had a terminal engine problem after about 4 hours and was withdrawn.

“After the first regular TA race, Donahue felt that his Camaro could be improved in the handling department. We arranged for them to bring the car to the GM proving grounds at Milford, Michigan for a few days of testing,” Bill says. By setting up round and rectangular skid pads, Donahue and an instrumentation team from R&D were able to significantly improve the cornering performance and the Penske cars dominated the remainder of the ‘68 season, also winning the championship. “I attended most of the races to tune the carburetors and provide feedback on component durability and performance. One of the major difficulties in Trans-Am was the requirement to run the production oil pan. The Camaro’s oil pan had the major part of the sump in the rear, where oil would normally flow under acceleration.” Notably, the Ford Mustangs, due to chassis design had their sump toward the front of the engine and suffered oil starvation under acceleration, which caused them many engine failures.”

Using the new aluminum 427’s, McLaren dominated the Can-Am series. They developed their own engine hardware including the Lucas-based fuel injection, intake manifolds and dry sump oiling systems. The majority of Chevy-powered Can-Am competitors used similar systems. The only problem experienced by the new Al engines was confined to cylinder liners not being firmly seated when they were initially installed. During the winter of 1968, McLaren built a new engine facility in Livonia, Michigan named McLaren Engines, headed by George Boltoff, formerly a TRACO employee. It had a new Heenan & Freude dyno, and was state of the art for 1968 outside of the major auto manufacturer facilities.

1968 Tulsa TA, Donahue and Bill’s brother

“Also that same year,” says Howell, “the Chevy dealer in Colorado Springs contacted us seeking assistance in the stock car portion of the Pikes Peak hill climb event. We had Smokey Yunick build a performance 427 MK IV engine to loan him and we supplied a prototype slap shifter for the transmission. The entire hill climb event lasts about a week, with practice every morning from daylight to 8:00 AM. Vince sent me out to oversee the engine tuning. The car was fastest on qualification day, but the shifter broke during the hill climb, so it was not a complete success.”

Again using temporary pattern equipment the following year, a new Al MK IV cylinder block cast was produced that would allow larger bores and more engine displacement, or a shorter stroke at the same displacement (430 CID). “We supplied them to, and sold them to other Can-Am competitors. McLaren again dominated the series, winning the championship. The majority of engine builders were using fully machined connecting rods manufactured by Carillo Ind. Some of them were experiencing fatigue failure of the bolts. McLaren had tried several bolt sources without success, so they came to us for help. We arranged for Standard Pressed Steel (an aerospace source) to do two sample designs using H-11 tool steel and Multiphase 35 (an aerospace alloy).” Fatigue testing proved their design superior in either alloy, and the racing connecting rod industry has universally adopted MP-35 as the alloy of choice for rod bolts. The alloy has another catchy name or two attached to it now by the con rod makers.

Smokey’s engine in 1968 Pikes Peak, Chevy Dealer in Colorado Springs

In 1969 Roger Penske’s team with Mark Donahue as primary driver, again dominated the Trans-Am. “In cooperation with TRACO we were able to refine their rebuild procedures and gain additional power through the season,” says Bill. “Typical TA engine power level by the end of season was about 450 BHP from 302 CID small block. We authorized Gene White Firestone to build and maintain another Camaro for the series, headquartered out of Atlanta, driven by NASCAR driver Pete Hamilton, and maintained by Jim Ruggles. It raced in a Daytona preliminary race in February (driven by Lloyd Ruby) in competition with a factory mustang driven by Parnelli Jones. It was competitive, however not successful during the TA season.”

Ford introduced their BOSS 302 engine in ‘69 and it had significantly more top end power, but with their cross-ram intake design, Chevy had a better torque curve, allowing them to be competitive. “Our driver, Donahue, made the difference,” exclaims Howell. “Again in 1969, I attended most of the races, and tuned the engines when no TRACO personnel were there. In 1969 or 70, our group was relocated to the R&D area of Chevrolet Engineering, as they were no longer involved in the Chapparal program. This gave us access to our own machining facilities and additional personnel. I also spent some time at Chris-Craft boats in Ft. Lauderdale, assisting them in adapting a performance 302 V8 engine to one of their 18 foot runabouts.”

Due to impending nationwide emission regulations, the 1970’s began with all GM facilities involved in reduced emission engine and vehicle development and Howell’s group had to step aside, losing access to their dynamometer facilities. “For performance engine development we were now forced to contract our work outside the GM Corp. Initially, we used McLaren Engines in Livonia, as we had verified the accuracy of their equipment.” Bruce McLaren was killed in a Can-Am vehicle-testing program in England, in the Spring. In addition to Can-Am, McLaren was now competing successfully in Indy car racing using turbocharged Offenhauser engines.

McLaren again dominated Can-Am racing with drivers Dennis Hulme, Peter Revson, and occasionally Dan Gurney. By now most teams were running at 494 CID and Chevy personnel were developing castings and pistons for use of A390 aluminum alloy. “These engines could run without cylinder liners or sleeves,” says Bill, “and promised greater durability at large displacements. I followed development of this and the sale and distribution of parts to the race teams. A390 aluminum alloy was scheduled to be used in production of the soon-to-be introduced Vega small car, and using it in Can-Am was to advertise its ability.”

The Penske Trans-Am program opted to switch to American Motors and run Javelins in 1970. “We contracted Jim Hall of Midland, Texas to run TA with 2 of the new 1970 Camaros. They built their own race engines. Hall drove one car, and Ed Leslie the second car. The rules for 1970 required the use of NASCAR style, 11 gallon, fuel dump cans which slowed down pit stops and allowed time for tire changes. Because of this, I developed a system to glue the lug nuts to the new wheels using 3M rubber cement. This eliminated physically handling the lug nuts individually and greatly quickened tire changes. We kept this system secret for most of the season, but it was later adopted by NASCAR, universally decreasing pit stop delays. (First used by Mario Rossi and the DiGard team). Our TA season was less than successful due to team expertise and some engine failures.” 1970 also marked the introduction of power steering to the TA. Ford won the championship with Parnelli Jones and George Fulmer driving. This was the last year of factory Chevy participation in TA.

Bill says, “once the corporation decided that maybe racing wasn’t all bad and it wasn’t going to cost them all their profits, Chevrolet decided that they wanted to keep their heavy-duty performance parts in the catalog after all, so consumers could buy from a dealer.”

Also about this same time, Smokey Yunick embarked on a project to run a carbureted twin-turbo small block Chevy at Indianapolis in the 500. “Herb Fishel in our group, followed that program,” claims Bill. “It was not successful due to the high g-forces on the low-pressure fuel in the carburetor.”

With the success of the Monte Carlo, other NASCAR teams switched to that design in 1973, but Johnson’s was the only Chevrolet supported team. Cale Yarborough drove their Monte to second place in the season standings. Chevy then became interested in NASCAR engine development and returned to their high performance programs, keeping much abreast of the sport and the goings on.

With the coming advent of the Vega, GM had contracted Cosworth Engineering of England to develop a 2 liter racing version using a Cosworth-designed cylinder head, and the Vega cylinder block in hopes it might be competitive in Formula 2 European racing and US midget car racing. “As part of the contract, they were to deliver three complete, race ready engines to us,” says Bill of his return to racing duties. “My job was to investigate the performance at McLaren, seek a competitive user in the US, and evaluate the potential for success in this country. The engines were dry sump with a Lucas-based, timed fuel injection, twin cam with four valves per cylinder. Cosworth designed the oil pan, oil pump, cylinder head, fuel injection (Lucas) and internal parts, including gas filled o-ring seals between head and cylinder block.”

“Through a friend in Dayton, Ohio (Marion Tucker), I was able to contact the Shannon Brothers, who owned a Buick dealership, and fielded a competitive USAC midget race car. Their mechanic and car builder was Bob Higman in Lafayette, Indiana. We were able to install a Cosworth built engine in their car and race it in a special race in Pocono, Pennsylvania and at the Thanksgiving race at Los Angeles. With John Rutherford driving, the engine and car were competitive, and we also learned that magnesium and methanol are not compatible. It ate holes in the oil pan on the way back from LA,” says Bill. “As development continued, we gradually replaced all Cosworth designed parts with US designs to make the engine practical in the US. Working with another car owner from the St. Louis area, Gene Hamilton, we continued development and won some races with Kenny Schrader driving. In the end the engine turned out too expensive for USAC midget racing and never sold well.”

The Cosworth Vega (US version) was scheduled to debut in 1974, but was delayed in production until 1975. It was a pleasant combination of performance and handling, all with 4-speed manual transmissions. Each one had a dash plate with its production number on it. Total production was about 3600 units. Howell provided a write-up on

build instructions and special parts for the Cosworth, and it was featured on the cover of the first official publication of the Chevrolet Power catalog introduced in 1974. Bill’s group continued various experiments on the Vega, to ultimately determine that it was not too impressive. Cale Yarborough won the NASCAR championship in Jr. Johnson’s Monte Carlo.

When the production version of Cosworth Vega was introduced in 1975, Howell had a turbocharged version in their group. “This was prior to wastegated versions, and digital electronic, but it was impressive in its operations nonetheless,” says Bill.

NASCAR restricted big block engines to the point that most competitors chose to switch to 358 CID small blocks. “Though we had done some 350 development in NASCAR trim at McLaren’s,” says Bill, “we were not aware of any particular shortcomings. I attended the 1975 Daytona 500 with Vince Piggins, to see the state of performance and development. Our performance was okay, but at least seven Chevy-powered cars had engine failures in the race. Upon return, we immediately started investigating components in this environment. We ultimately decided to prepare six complete engines that we would loan out to competitors in 1976 and learn first-hand what needed to be changed. The Ford teams had a box type intake manifold with a large plenum that appeared to have more power than the Chevrolets. Jr. Johnson lobbied NASCAR to let him design and have manufactured a similar intake for Chevy, on the condition that any Chevy team could buy one from him. Intake manifold design was virtually unregulated at that time. We purchased six units from Johnson for our 1976 development and durability engines. Along with the intakes, the carbs were free (limited to a maximum bore size at the mounting flange). Through our testing of various combinations, we determined that fuel and air mixture distribution was going to be a problem, so we developed various modifications to the carb that looked acceptable on the dyno.”

“In 1976, we loaned our NASCAR durability engines to Jr. Johnson, AJ Foyt, DiGard Racing, CooCoo Marlin and James Hylton before Daytona in February,” says Bill. “At Daytona, it became apparent that the centrifugal force in the turns was altering the mixture distribution seriously and only a couple engines were included in the race. Returning to McLaren, we mounted a development engine at a 45-degree angle on the dyno, simulating 1g cornering forces. We were then able to correct the mixture problem with grooves and dams in the manifold. As an added benefit, we discovered that the stock floats in the Holley carb were restricting fuel flow at cornering loads. I was able to alter the float shape to correct the problem, and this change was adopted by Holley as a float option in their parts list. As the 1976 NASCAR season progressed, we were able to tear down and evaluate engines with enough miles on them, to sort out several durability improvements. One of significance was the size of the water cooling line from the engine to the radiator top tank. The car builders had been using a #16 Aeroquip hose for this purpose, and it was restricting water flow enough that the rear four pistons in the engines were showing cracks on teardown. This was discovered on our DiGard durability test engine. We continued to do all of our development testing at McLaren

Engines in Livonia. Most NASCAR teams were now running the current model Monte Carlo on shorter tracks and Chevelles at Daytona on longer tracks.”

Chevrolet did not sponsor teams beyond the Jr. Johnson team, as it was not necessary due to Chevy product performance, and the fact that they were already winning the championship.

In addition to performance engine work, Howell was responsible for all the engine instructions and most of the part numbers in the rewrites of the Chevrolet Power catalog, revised every other year or so. Bill says, “I also fielded phone calls from many of the racing engine builders around the country who specialized in Chevrolet engines whether circle track or road race, but not many drag racers. Ron Sperry, in our group, catered to the drag racers.”

Drivers meeting ASA

In the mid to late 1970’s, Chevy began to pay attention to the smaller organizations running organized short track racing such as ASA, ARCA, ARTGO in the Midwest, and ACT, in the New England area, as they were primary users of Chevy’s heavy duty performance parts. “Since ASA was the most predominant in the Midwest,” says Bill, “In 1977 I contacted Rex Robbins, who headed the organization, in an attempt to become familiar with their series and competitors. They and most of the other series had recently restricted their engine compression ratios to 9.5:1, and were struggling to find a foolproof inspection method to prevent cheating on CR. This began a long relationship between various GM divisions and ASA with component and brand sponsorships that helped maintain GM as the predominant brand in short track racing. We maintained contact in various ways until ASA was sold after 2002. We were also requested by Chevy Truck to look into off-road and truck racing in the Western US, so I took a trip to California to visit the off-road manufacturers and watch an event at Riverside. This familiarized us with their requirements. This put us in contact with Joe McPherson Chevy and Ron Shaver engines on the West coast. We were already acquainted with the Champion Dyno facility in Long Beach through TRACO Engineering. Over the years, I met and visited the majority of engine builders and shops in California.”

Above: Jack Ingraham

Below: Darrel Waltrip and sportsman V6 car

GM downsized all its intermediate cars in 1978. The Monte Carlo was now a boxy shape, and the Chevelle had a flat nose on it. NASCAR extended the eligibility of the older Monte Carlo’s for a couple of years, but most GM oriented teams switched to either Buick or Oldsmobile sheet metal to gain a more sloped nose with better down force. “Since Chevrolet was not investing a great amount of money in NASCAR racing,” says Bill, “we had no clout with the race teams. Buick however, was now helping Jr. Johnson and a couple of other teams to get their sheet metal out front and improve their performance image.”